Step Conveyors

Melvia designs and manufactures conveyor systems for the confectionery and bakery industries - from simple conveyors to extensive automated systems.

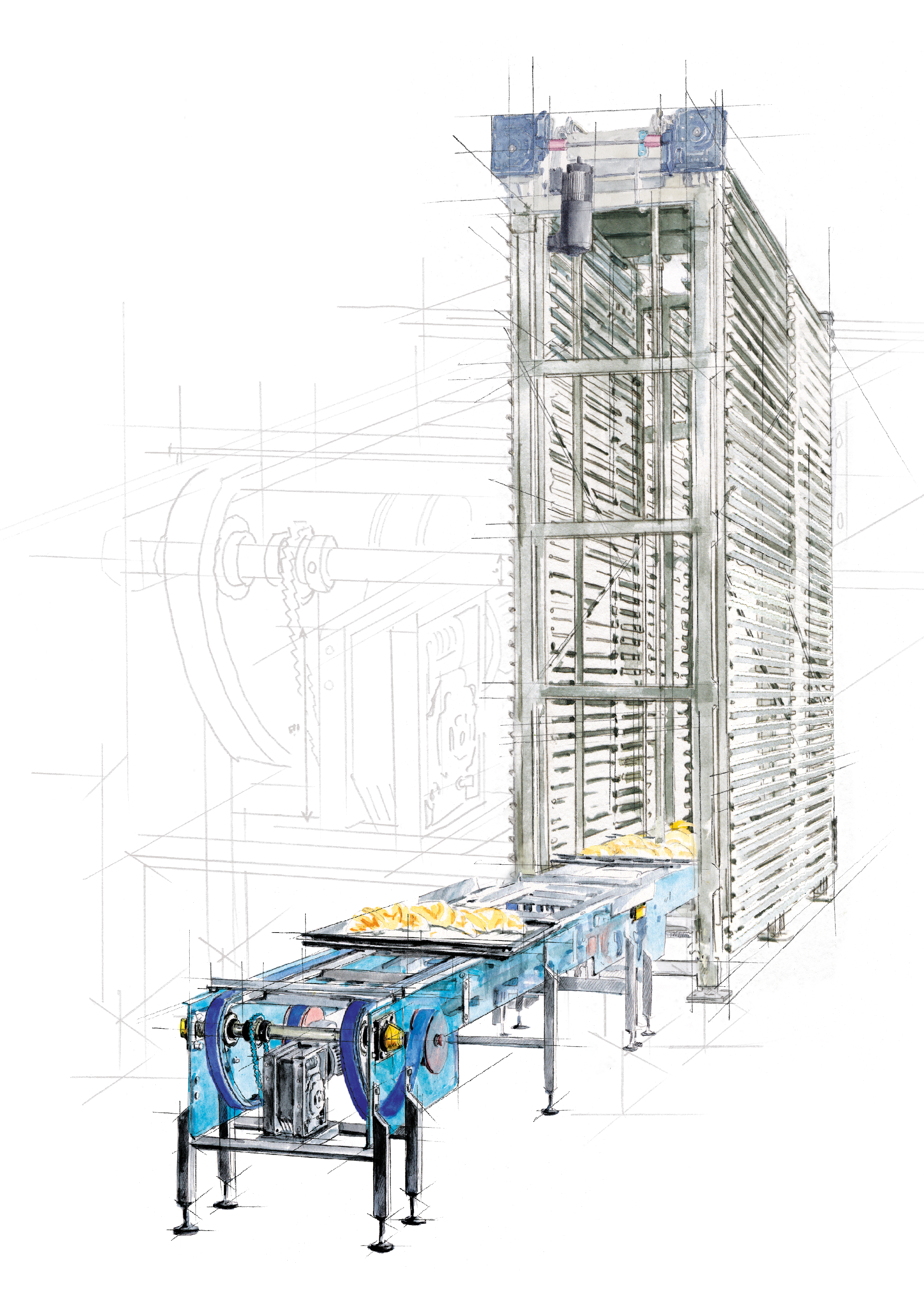

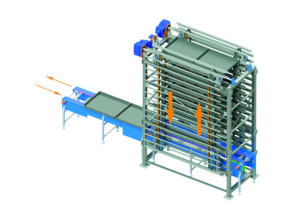

An important part of production lines are Multi-Step systems, which are also known as paternosters. Paternosters became a global food production trend. Melvia provides a full range of Multi-Step systems. Systems are custom made, designed and produced to meet the high safety and stringent hygiene requirements of the production process.

The general principle of all systems is a system for moving product carriers (sections of forms, trays, etc.) using parallel chains with grippers located on two opposite sides of the paternoster, which form tiers. Due to the fact that the step speeds are individually adjustable for each section, this allows for a wide range of proofing or cooling processes to be configured. Systems operate on a “step” principle.

key features

- The compact design of the cabinet allows for maximising use of the available height of the room with a significantly reduced floor space footprint.

- The systems are well suited for production lines with both high and low production rates

- Using different types of molds and trays.

- Consistent regulation of time, temperature, and humidity

- Reliable and durable construction

Gallery

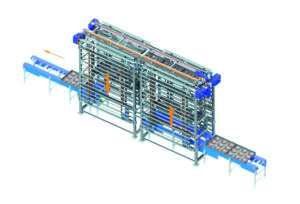

Known as FIFO. The carriers are fed at regular intervals to the conveyor of the ascending section, where a row is formed. After a row is set, the holders step up and move in steps until the section is completely filled. Subsequently with the help of a horizontal pusher, the carriers are moved to the descending section, which lowers the product carriers onto the output conveyor. Smooth movements throughout the system ensure very gentle dough handling. Formation of a row is possible by fixing the extreme position with a stopper, or conveyors with partitions.

Known as FIFO. The carriers are fed at regular intervals to the conveyor of the ascending section, where a row is formed. After a row is set, the holders step up and move in steps until the section is completely filled. Subsequently with the help of a horizontal pusher, the carriers are moved to the descending section, which lowers the product carriers onto the output conveyor. Smooth movements throughout the system ensure very gentle dough handling. Formation of a row is possible by fixing the extreme position with a stopper, or conveyors with partitions.

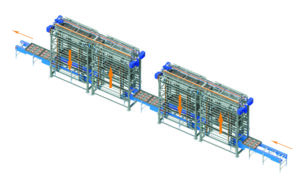

A block system consists of at least two linear sections. Groups of product carriers are stopped on the infeed conveyor in smaller batches. Af ter exiting the first section, the trays enter the second section, where they will again move up and down using a stepping mechanism. This process can be continued as many times as required for the production line. There is a long conveyor under all sections, fitted with stoppers under each ascending section. One of the great advantages of a multi-block system is that sections can be bypassed if necessary.

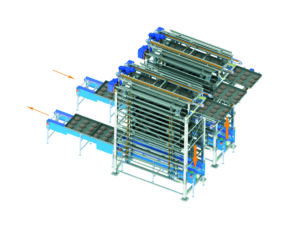

It is a compact version of the linear system. The ascending and descending sections are parallel to each other. The mechanism for moving carriers between sections is a transfer conveyor. The rest of the operation is the same as in the „linear“ system.

It is a compact version of the linear system. The ascending and descending sections are parallel to each other. The mechanism for moving carriers between sections is a transfer conveyor. The rest of the operation is the same as in the „linear“ system.

This system called FILO or buffer. The system has only one branch, which has a reversible direction of movement. Buffer systems are used as storage facilities if lines are stopped or product carriers are changed. They can also work as a compensating element when the need for the number of carriers in the production cycle changes. When there is an excess of carriers in the line, the synchronization conveyor fills up and a step, or several steps upward – a reception cycle. When the demand for sheets in the line increases, the system will start working in delivery mode.

This system called FILO or buffer. The system has only one branch, which has a reversible direction of movement. Buffer systems are used as storage facilities if lines are stopped or product carriers are changed. They can also work as a compensating element when the need for the number of carriers in the production cycle changes. When there is an excess of carriers in the line, the synchronization conveyor fills up and a step, or several steps upward – a reception cycle. When the demand for sheets in the line increases, the system will start working in delivery mode.